How Tyres Are Made

The tyres on your car might seem like simple rubber circles, mass produced in a moulding machine with no distinguishable characteristics other than a tread pattern, but in reality they are carefully constructed using a series of different processes and up to 200 raw materials.

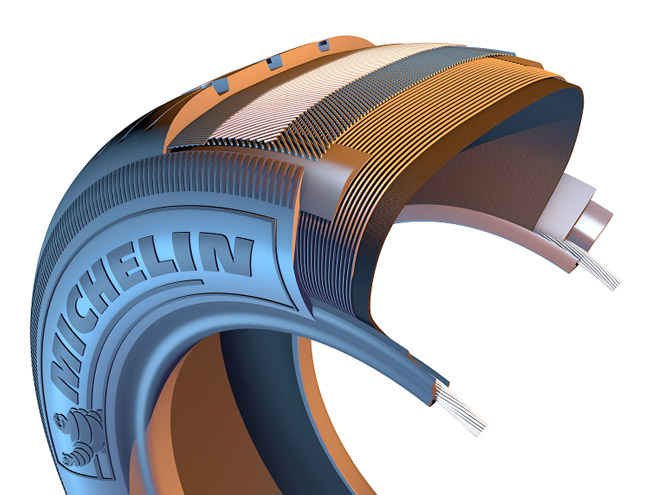

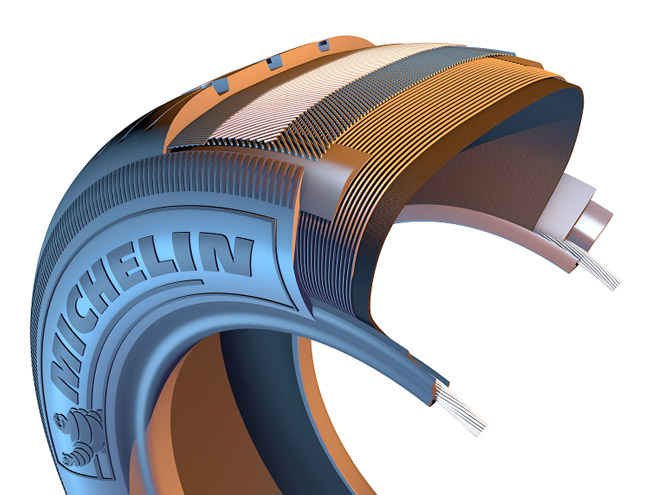

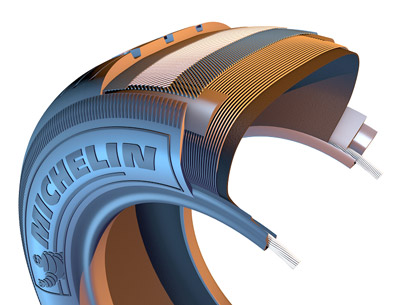

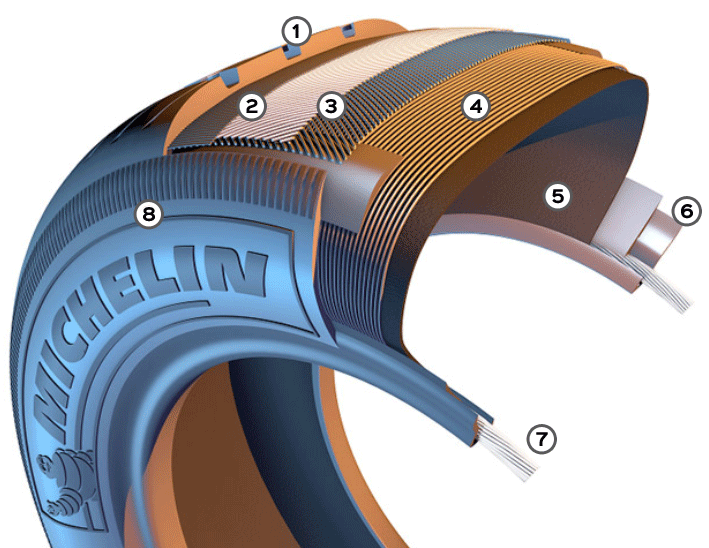

- Tread design incorporates grooves to remove water between the tyre and the road surface

- Zero degree belt found on top of bracing plies in some tyres helps the tyre to maintain its shape at high speeds by resisting centrifugal growth.

- Bracing plies made from a series of polyester cords, reinforced with steel and encased in rubber make the tread surface flatter increasing the contact patch with the road

- Radial casing plies contain textile fibre cords that give the tyre strength and enable the tyre to resist pressure.

- Inner liner made of a synthetic rubber design to keep air in the tyre. Think of it as a kind of inner tube.

- Bead protector rubber rim strips protect the bead from minor shocks

- Steel bead wires hold the tyre onto the wheel rim. They can bear a load of up to 1800kg.

- Sidewall rubber is constructed from an abrasion-resistant compound providing protection against scuffs and curb damage.

Each tyre model is different and tyre manufacturers invest heavily in research and development to create the best tyres for different driving conditions. When designing a new tyre, one of the key components is the mixture of rubber compounds used in the tyre which is balanced to optimise steering, braking, road handling and wear capabilities. Other key components of a tyre include the steel bead wires which hold the tyre on the rim of the wheel, the casing ply that gives the tyre strength, and the bracing plies which maximise the tyre’s contact patch with the road.

On the outside of the tyre, grooves and tread sipes on the shoulder of the tyre are specially designed to channel water away from the surface of the tyre, maintaining maximum wet grip. The contact patch is also designed to resist general wear and tear and cope with high temperatures generated by friction.

Remember, your tyres are the only contact between your car and the road so it’s essential that they provide sufficient grip and road handling. Your tyres are also designed to deliver a comfortable ride, yet be as robust and hard-wearing as possible, maintaining safe and controlled manoeuvrability for your vehicle.