How Does an Engine Work?

Bradley Jando | Tuesday 9th March 2021 4:02pm

The internal combustion engine is relied on by hundreds of millions of vehicles on a daily basis. Itís a relatively efficient way of turning the energy stored in fuel into kinetic energy to help get cars moving. As its name suggests, it contains mini explosions, and turns the energy from those explosions into different forces. As weíre seeing now with electric cars, itís not the only way to move a car Ė but until quite recently (and perhaps for a while yet) itís been the most efficient way of moving a car.

So how exactly does a car engine work?

Engine motion is cyclical

The first thing to remember is that engine motion is cyclical. Or at least that an engine generates momentum in its systems that helps to keep itself going. Itís why when, for example, youíre just about to stall your car, youíre able to keep it going by either pressing down on the clutch pedal or by pressing the accelerator pedal. What youíre doing with these actions is either reducing the load on the engine (pressing the clutch down), or adding more fuel to the engine (pressing the gas pedal down). Both of which help maintain the momentum.

Fundamentally, an engine converts the linear motion of the pistons into rotational motion, which then rotates other parts of the engine through the use of belts.

Letís break down what these systems are.

Cylinders

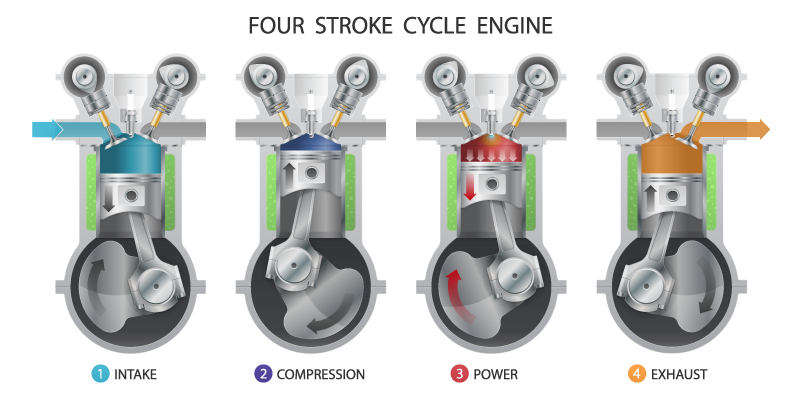

Engines have a number of cylinders in a row. These cylinders are quite literally the heart of an engine. Most car engines function with a four-stroke cylinder motion. This means that each cylinder cycles between four stages. These are Intake, Compression, Power, Exhaust.

Visually, it looks like this:

Here, you can see the motion in one cylinder. The cylinders contain a piston that moves up and down. Itís sort of like a syringe plunger in the way that it creates a vacuum in the chamber. As the piston moves down, it sucks a fuel-air mixture into the chamber from the intake valve (on the left). It then compresses that fuel-air mixture on the way up (which makes it easier to ignite).

A spark plug at the top of the chamber then ignites fuel-air mixture, which causes a miniature explosion that pushes the piston back down.

On its way up, the piston pushes the exhaust fumes out of the exhaust vent.

So the cylinder completes four ďstrokesĒ in a cycle.

This is hopefully making sense so far. The question now is: how does the piston move up and down in order to pull in the fuel?

Crankshaft

Car engines have a number of cylinders, from three cylinders on some hatchbacks up to 16 cylinders on high-end sports cars (like the W16 engine in Bugatti Veyrons). The more cylinders you have in an engine, the more volume of fuel can be burned at any one time Ė this means more power can be generated.

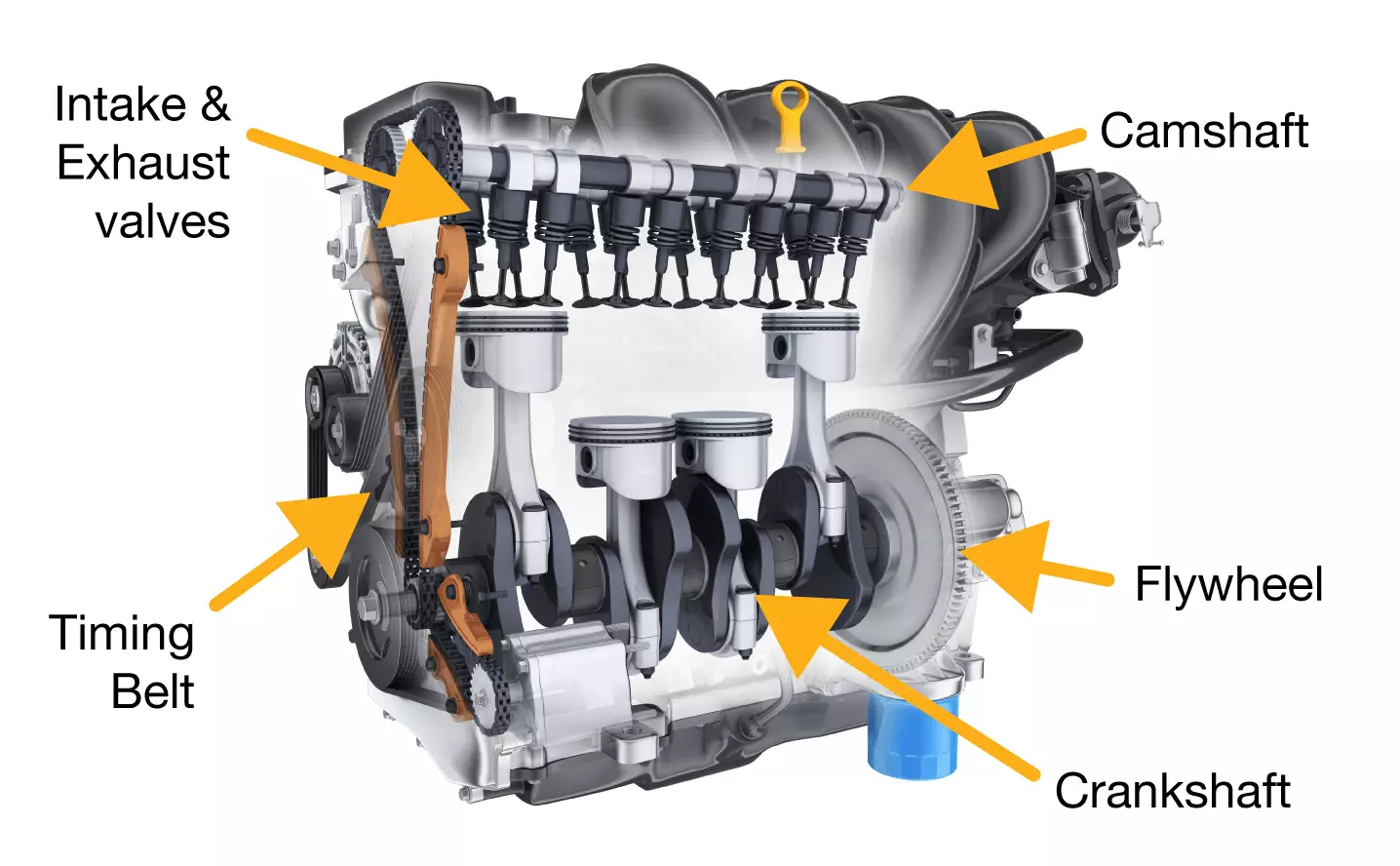

These cylinders are aligned in a number of configurations along a crankshaft. This is a rod that is rotated by the pistons. Usually, theyíre configured so that as one piston is going down, another piston is going up. This helps to both balance the forces and maintain the momentum of the system.

To further help maintain the momentum, the crankshaft is connected to a flywheel on one end thatíll help keep the entire crankshaft rotating if thereís a slight dip in power. This momentum means that, once the engine is going, the momentum pulls some pistons down in order to pull fuel in, while others are going up to compress fuel thatís already been pulled in.

As such, an engine keeps itself going once it has started, so long as thereís a continuous supply of fuel and no blockages in the exhaust line. Any blockages in the exhaust line mean that the cylinders get filled with fumes, and canít draw in new fuel.

The cog at the other end of the crankshaft is connected via a belt to the other parts of the engine. Itís also whatís used to actually start the engine.

Before starter motors, people used to have to manually crank the crankshaft to get it going. But now we use the electricity from the car battery to power a strong electric motor that turns the crankshaft enough to get the engine going. Once the engineís going, the starter motor disengages and the engine runs in an idling state.

Camshaft

The crankshaft is connected to rods above the cylinders via a timing belt. These rods are called ďcamshaftsĒ and are used to control the opening and closing of the intake and exhaust valves. Using this method means that you donít have to rely on a secondary computer to tell the valves when to open (though thatís now becoming significantly more reliable) Ė theyíre manufactured so that the valves have to open and close in a way thatís perfectly synchronised with the movement of the pistons.

Hereís a view of all the parts connected Ė though imagining we could see through the cylinders.

This is the engine itself. Itís what keeps everything ticking but, of course, there are a number of auxiliary systems that make sure everything runs smoothly to and from the engine. In diesel engines, for example, the diesel goes through a warming process via glow plugs before getting to the engine cylinders. Thatís because diesel is much less flammable at room temperature, while petrol is extremely flammable (itíll evaporate if left open, for example). Other than that, and a few minor differences in gaskets due to the corrosive properties of petrol, diesel and petrol engines function in fundamentally the same way.

Need some help with your engine?

Understanding how an engine works makes it a lot easier to diagnose problems, but it is still always a good idea to seek expert advice if youíre concerned about problems with your engine.

If you need to get a fault fixed, call your local Kwik Fit centre.

Any facts, figures and prices shown in our blog articles are correct at time of publication.

Featured Articles

Is it Illegal to Drive With One Headlight?

Saturday 19th July 2025

Wondering if itís illegal to drive with one headlight? Learn about the safety risks and penalties of illegal blown bulbs and why you should fix them promptly.

Air Con in EVs & Hybrids: Experts Answer Your Questions

Monday 30th June 2025

Does air con drain EV batteries? Can you use the air con while charging an electric car? Find out the answers to these questions & more from Kwik Fitís experts.

Why Is Your Car Making a Noise? Fixes & Tips

Friday 13th June 2025

When your car starts making unexpected noises, it can certainly be quite disconcerting; it may be nothing to worry about, but hereís what you need to know.