Could Airless Tyres Put An End To Punctures?

Jack Dreyer | Friday 26th August 2022 8:00am

A punctured tyre is a surefire way to deflate your plans for the day. It’s not the end of the world, but with many spare tyres being replaced with repair kits that are difficult to use, a puncture often means a lengthy roadside DIY repair process or a call for assistance. But new tyres being developed by Michelin could put an end to punctures altogether.

What are the real benefits of these airless tyres, and how does the technology work?

Punctures lead to waste

Tyre punctures, specifically with damage to sidewall, are a huge cause of tyres needing to be wasted. And even though many are recycled, up to 11% in the US end up in landfill, which equates to about 27m tyres in the US alone. The numbers for the UK are likely to be much fewer due to the smaller population, but will still be the same proportionally. Needless to say, tyre waste is a real problem globally.

Energy is used to source the raw materials, make them into tyres in the first place, and even used when recycling the tyres. So as few tyres that need to be remade or converted the better!

Incorrectly inflated tyres waste fuel

In addition to the problems of punctures, even something as seemingly benign as incorrectly inflated tyres can cause a range of issues. Most usually, incorrect tyre pressure can lead to excessive or uneven tyre wear: overinflation causes excessive wear in the centre of the tyre tread, whereas underinflation causes wear on the outside of the tyre as the outside bulges outwards.

Most worryingly, incorrectly inflated tyres are a huge drain on fuel or brakes. Underinflated tyres have consistently more contact with the road, which creates more friction that needs to be overcome by the engine. Conversely, overinflated tyres have very little contact with the road, which means the brakes need to be engaged much more frequently, strongly, and for longer, in order to safely slow the car down.

What are airless tyres?

You can read more on the history of tyres in this other blog but, originally, tyres for bicycles were solid rubber. John Boyd Dunlop invented the first pneumatic tyres for bicycles in 1887 and, when technological advances made it feasible, these were introduced for wider use on vehicles in the mid-20th century.

Modern tyres are made with a variety of layers and interlocking materials. The core purpose here is to create a tyre that is flexible enough to account for debris and unevenness on roads but rigid enough to hold up the weight of a vehicle when inflated.

A lip around the edge of the tyre locks into a receiving lip on the wheel rim so that when you inflate the tyre it stays put. When correctly inflated, there are lots of benefits of tyres being held up with air. But Michelin are anticipating being able to provide all the same benefits without any of the problems of incorrect tyre pressure or the possibility of blowouts!

But how?

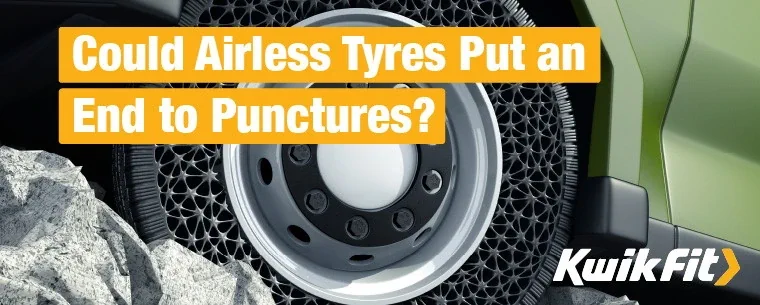

Their tyre prototypes feature a futuristic-looking mesh design that provides a similar buoyancy to air and a similar performance in normal use cases but without any of the negatives! It’s actually a design that was first developed by NASA for use on rovers more than a decade ago!

What’s the problem with airless tyres?

There are a few problems with the tyres, however, that means they’re still in development – with Michelin hoping to get them in the market by 2024. The main issue seems to be accounting for the sideways forces that are exerted on the tyres as you round corners. Tyres need to bulge sideways a little – but not too much – in order to keep the car safely in contact with the road. If the tyres are too rigid, the car is likely to go into a skid at every corner.

It seems to have proven challenging to mimic in a handling style that’s as predictable as it is with air-filled tyres.

Nevertheless, this technology has a lot of potential – Michelin has even suggested that, with the use of 3D printing technology, it would be possible to reprint tyre tread when it’s worn instead of having to recycle or waste the entire tyre. That alone is a promising step to a greener future. We’re looking forward to seeing how Michelin get there in the coming few years.

If you have any questions about your current set of tyres, however, get in touch with the experts at your local Kwik Fit centre today.

Any facts, figures and prices shown in our blog articles are correct at time of publication.

Featured Articles

Is it Illegal to Drive With One Headlight?

Saturday 19th July 2025

Wondering if it’s illegal to drive with one headlight? Learn about the safety risks and penalties of illegal blown bulbs and why you should fix them promptly.

Air Con in EVs & Hybrids: Experts Answer Your Questions

Monday 30th June 2025

Does air con drain EV batteries? Can you use the air con while charging an electric car? Find out the answers to these questions & more from Kwik Fit’s experts.

Why Is Your Car Making a Noise? Fixes & Tips

Friday 13th June 2025

When your car starts making unexpected noises, it can certainly be quite disconcerting; it may be nothing to worry about, but here’s what you need to know.